Our export model is the Avmount Machine Mounts: Type AMM. Like all other

models this model too helps to make the environment free from inherent and external

vibrations. Besides, the mounts also consist of oil and age resistant synthetic rubber.

The compact mounts help in the optimal absorption of vibrations.

Our export model is the Avmount Machine Mounts: Type AMM. Like all other

models this model too helps to make the environment free from inherent and external

vibrations. Besides, the mounts also consist of oil and age resistant synthetic rubber.

The compact mounts help in the optimal absorption of vibrations.

Dimensions of Export Model (Type AMM)

Technical Specifications of Export Model (Type AMM)

| Avmount Machine Mounts | AMM-10 | AMM-20 | AMM-30 | AMM-40 |

| Diameter | 80 mm | 120 mm | 160 mm | 200 mm |

| Min. Height Above the Floor | 38 mm | 46 mm | 53 mm | 63 mm |

| Adjustable Level | 38-50 mm | 46-59 mm | 53-68 mm | 63-78 mm |

| Bolt Thread: Standard | M12 X 1.25 | M16 X 1.5 | M20 X 1.5 | M20 X 1.5 |

| Optional | - | M12 X 1.25 | M16 X 1.5 | M16 X 1.5 |

| Bolt Length | 125 mm | 125 mm | 175 mm | 175 mm |

| Loading/Mount Machine Tool | 50-500 kg | 400-1000 kg | 800-2000 kg | 1500-4000 kg |

| Loading/Mount Power Presses | ||||

| Max. Strokes/Min. 200 | 50-120 kg | 100-250 kg | 250-725 kg | 500-1400 kg |

| 160 | 60-140 kg | 120-350 kg | 350-1100 kg | 750-2100 kg |

| Less than 125 | 70-200 kg | 200-400 kg | 400-1400 kg | 1000-2800 kg |

Mounting Procedure for Export Model (Type AMM)

1. Lift the machine above the floor.

2. Screw down the bolts into their respective guides.

3. Lower the machine so that it rests on the machine mounts.

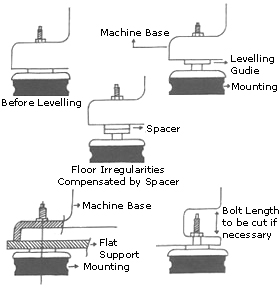

4. Level the machine using a precision spirit level as illustrated.

5. Tighten the lock nut after levelling, to prevent any alterations in level while in operation.

6. The adjustable height of our mounting is as follows:

| AMM 10 | AMM 20 |

| 38-50 mm | 46-59 mm |

| AMM 30 | AMM 40 |

| 53-68 mm | 63-78 mm |

Should the levelling exceed this limit because of an uneven floor, then a spacer of appropriate diameter and thickness should be inserted between the machine base and the mount, to compensate for the difference in the floor level at any support point.

7. In some machines, the design of the base is hollow and the bolt hole provided is such that the mounting cannot be directly fixed to the base. In such cases, the machine is made to rest on an adequate size of flats and the mountings placed under them. The rest of the procedure is the same as discussed. The illustration is shown.

8. If the bolt lengths are more, the chamfered end may be cut to suit the machine. After cutting it to the required length, form a radius to suit the cup. This is necessary in the case of machine bases where pockets are provided.

Click here to find the right kind of mount for your machine